Wednesday, 23 May 2012

Tuesday, 22 May 2012

types of engine

Internal Combustion Engine

Internal combustion engines are one of the

building blocks of modern civilization. In an internal combustion

engine, the combustion takes place inside a confined chamber. All

internal combustion engines burn a mixture of air & fuel. The fuel

can be gasoline, diesel, methane, propane etc.

The piston is the heart of an internal combustion

engine..The concept of the piston engine is that a supply of

air-and-fuel mixture is fed to the inside of the cylinder where it is

compressed and then burnt. This internal combustion releases heat energy

which is then converted into useful mechanical work as the high gas

pressures generated force the piston to move along its stroke in the

cylinder. It can be said, therefore, that a heat-engine is merely an

energy transformer.

To enable the piston movement to be harnessed,

the driving thrust on the piston is transmitted by means of a

connecting-rod to a crankshaft whose function is to convert the linear

piston motion in the cylinder to a rotary crankshaft movement (Fig.

1.1-1). The piston can thus be made to repeat its movement to and fro,

due to the constraints of the crankshaft crankpin’s circular path and

the guiding cylinder.

The backward-and-forward displacement of the

piston is generally referred to as the reciprocating motion of the

piston, so these power units are also known as reciprocating engines.

The internal combustion engine is an engine in which the combustion of a fuel (normally a fossil fuel) occurs with an oxidizer (usually air) in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine. This force is applied typically to pistons, turbine blades, or a nozzle. This force moves the component over a distance, transforming chemical energy into useful mechanical energy. The first functioning internal combustion engine was created by Étienne Lenoir.[1]

The internal combustion engine is an engine in which the combustion of a fuel (normally a fossil fuel) occurs with an oxidizer (usually air) in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine. This force is applied typically to pistons, turbine blades, or a nozzle. This force moves the component over a distance, transforming chemical energy into useful mechanical energy. The first functioning internal combustion engine was created by Étienne Lenoir.[1]

The term internal combustion engine usually refers to an engine in which combustion is intermittent, such as the more familiar four-stroke and two-stroke piston engines, along with variants, such as the six-stroke piston engine and the Wankel rotary engine. A second class of internal combustion engines use continuous combustion: gas turbines, jet engines and most rocket engines, each of which are internal combustion engines on the same principle as previously described.[1]

The internal combustion engine (or ICE) is quite different from external combustion engines, such as steam or Stirling engines, in which the energy is delivered to a working fluid not consisting of, mixed with, or contaminated by combustion products. Working fluids can be air, hot water, pressurized water or even liquid sodium, heated in some kind of boiler.

A large number of different designs for ICEs have been developed and built, with a variety of different strengths and weaknesses. Powered by an energy-dense fuel (which is very frequently gasoline, a liquid derived from fossil fuels). While there have been and still are many stationary applications, the real strength of internal combustion engines is in mobile applications and they dominate as a power supply for cars, aircraft, and boats.

another defination

Animation of two-stroke engine in operation, with a tuned pipe exhaust

An automobile engine partly opened and colored to show components.

The term internal combustion engine usually refers to an engine in which combustion is intermittent, such as the more familiar four-stroke and two-stroke piston engines, along with variants, such as the six-stroke piston engine and the Wankel rotary engine. A second class of internal combustion engines use continuous combustion: gas turbines, jet engines and most rocket engines, each of which are internal combustion engines on the same principle as previously described.[1]

The internal combustion engine (or ICE) is quite different from external combustion engines, such as steam or Stirling engines, in which the energy is delivered to a working fluid not consisting of, mixed with, or contaminated by combustion products. Working fluids can be air, hot water, pressurized water or even liquid sodium, heated in some kind of boiler.

A large number of different designs for ICEs have been developed and built, with a variety of different strengths and weaknesses. Powered by an energy-dense fuel (which is very frequently gasoline, a liquid derived from fossil fuels). While there have been and still are many stationary applications, the real strength of internal combustion engines is in mobile applications and they dominate as a power supply for cars, aircraft, and boats.

Comparison of SI and CI Engine

Comparison of SI and CI Engine

Comparison of S.I. and C.I. engines is made from various aspects is made below:

Fuel economy

The chief

comparison to be made between the two types of engine is how effectively

each engine can convert the liquid fuel into work energy. Different

engines are compared by their thermal efficiencies. Thermal efficiency

is the ratio of the useful work produced to the total energy supplied.

Petrol engines can have thermal efficiencies ranging between 20% and

30%. The corresponding diesel engines generally have improved

efficiencies, between 30% and 40%. Both sets of efficiency values are

considerably influenced by the chosen compression-ratio and design.

Power and torque

The

petrol engine is usually designed with a shorter stroke and operates

over a much larger crankshaft-speed range than the diesel engine. This

enables more power to be developed towards the upper speed range in the

petrol engine, which is necessary for high road speeds; however, a

long-stroke diesel engine has improved pulling torque over a relatively

narrow speed range, this being essential for the haulage of heavy

commercial vehicles.

At the time of writing, there was a trend to

incorporate diesel engines into cars. This new generation of engines has

different design parameters and therefore does not conform to the above

observations.

Reliability

Due to

their particular process of combustion, diesel engines are built

sturdier, tend to run cooler, and have only half the speed range of most

petrol engines. These factors make the diesel engine more reliable and

considerably extend engine life relative to the petrol engine.

Pollution

Diesel

engines tend to become noisy and to vibrate on their mountings as the

operating load is reduced. The combustion process is quieter in the

petrol engine and it runs smoother than the diesel engine. There is no

noisy injection equipment used on the petrol engine, unlike that

necessary on the diesel engine.

The products of combustion coming out of the exhaust system are

more noticeable with diesel engines, particularly if any of the

injection equipment components are out of tune. It is questionable which

are the more harmful: the relatively invisible exhaust gases from the

petrol engine, which include nitrogen dioxide, or the visible smoky

diesel exhaust gases.

Safety

Unlike petrol,

diesel fuels are not flammable at normal operating temperature, so they

are not a handling hazard and fire risks due to accidents are minimized.

Cost

Due to their heavy construction and injection equipment, diesel engines are more expensive than petrol engines.

Difference b/w 2 & 4 stroke petrol engine

Difference Between Two & Four Stroke Cycle Petrol Engines

The differences between two- and

four-stroke-cycle petrol engines regarding the effectiveness of both

engine cycles are given below:

a) The two-stroke engine

completes one cycle of events for every revolution of the crankshaft,

compared with the two revolutions required for the four-stroke engine

cycle.

b) Theoretically, the two-stroke

engine should develop twice the power compared to a four-stroke engine

of the same cylinder capacity.

c) In practice, the two-stroke

engine's expelling of the exhaust gases and filling of the cylinder with

fresh mixture brought in through the crankcase is far less effective

than having separate exhaust and induction strokes. Thus the mean

effective cylinder pressures in two-stroke units are far lower than in

equivalent four-stroke engines.

d) With a power stroke every

revolution instead of every second revolution, the two-stroke engine

will run smoother than the four-stroke power unit for the same size of

flywheel.

e) Unlike the four-stroke

engine, the two-stroke engine does not have the luxury of separate

exhaust and induction strokes to cool both the cylinder and the piston

between power strokes. There is therefore a tendency for the piston and

small-end to overheat under heavy driving conditions.

f) Due to its inferior scavenging process, the two-stroke engine can suffer from the following:

i) inadequate transfer of fresh mixture into the cylinder,

ii) excessively large amounts of residual exhaust gas remaining in the cylinder,

iii) direct expulsion of fresh charge

through the exhaust port.

These undesirable conditions may occur under different speed and

load situations, which greatly influences both power and fuel

consumption.

g) Far less maintenance is

expected with the two-stroke engine compared with the four-stroke

engine, but there can be a problem with the products of combustion

carburizing at the inlet, transfer, and exhaust ports.

h) Lubrication of the two-stroke

engine is achieved by mixing small quantities of oil with petrol in

proportions anywhere between 1:16 and 1:24 so that, when crankcase

induction takes place, the various rotating and reciprocating components

will be lubricated by a petrol-mixture mist. Clearly a continuous

proportion of oil will be burnt in the cylinder and expelled into the

atmosphere to add to unwanted exhaust emission.

i) There are fewer working parts

in a two-stroke engine than in a four-stroke engine, so two-stroke

engines are generally cheaper to manufacture.

valve timing diagram

Valve timing diagram of a four stroke engine

gives a clear idea about the actual position of the piston during the

opening & closing of inlet & exhaust valves. In practice, the

events of the four-stroke cycle do not start and finish exactly at the

two ends of the strokes - to improve the breathing and exhausting, the

inlet valve is arranged to open before TDC and to close after BDC and

the exhaust valve opens before BDC and closes after TDC. These early and

late opening and closing events can be shown on a valve timing diagram

such as Fig. 1.1-4.

Valve lead This is where a valve opens so many degrees of crankshaft rotation before either TDC or BDC.

Valve lag This is where a valve closes so many degrees of crankshaft rotation after TDC or BDC.

Valve overlap This is

the condition when both the inlet and the exhaust valves are open at the

same time during so many degrees of crankshaft rotation.

compression ratio

Compression-ratio is a very important parameter

for measuring engine performance.The compression-ratio may be defined as

the ratio of the maximum cylinder volume when the piston is at its

outermost position (BDC) to the minimum cylinder volume (the clearance

volume) with the piston at its innermost position (TDC) - that is, the

sum of the swept and clearance volumes divided by the clearance volume,

Vs þVc i:e: CR ¼ Vc

where CR ¼ compression ratio

Vs ¼ swept volume (cm3) Vc ¼ clearance volume (cm3)

Petrol engines have compression-ratios of the

order of 7:1 to 10:1; but, to produce self-ignition of the charge,

diesel engines usually double these figures and may have values of

between 14:1 and 24:1 for naturally aspirated (depression-induced

filling) types, depending on the design.

In an engine cylinder, the gas molecules are

moving about at considerable speed in the space occupied by the gas,

colliding with other molecules and the boundary surfaces of the cylinder

head, the cylinder walls, and the piston crown. The rapid succession of

impacts of many millions of molecules on the boundary walls produces a

steady continuous force per unit surface which is known as pressure

(Fig. 1.1-12).

When the gas is compressed into a much smaller

space, the molecules are brought closer to one another. This raises the

temperature and greatly increases the speed of the molecules and hence

their kinetic energy, so more violent impulses will impinge on the

piston crown. This increased activity of the molecules is experienced as

increased opposition to movement of the piston towards the cylinder

head.

The process of compressing a constant mass of gas

into a much smaller space enables many more molecules to impinge per

unit area on to the piston. When burning of the gas occurs, the chemical

energy of combustion is rapidly transformed into heat energy which

considerably increases the kinetic energy of the closely packed gas

molecules. Therefore the extremely large number of molecules squeezed

together will thus bombard the piston crown at much higher speeds. This

then means that a very large number of repeated blows of considerable

magnitude will strike the piston and so push it towards ODC.

This description of compression, burning, and

expansion of the gas charge shows the importance of utilising a high

degree of compression before burning takes place, to improve the

efficiency of combustion. The amount of compression employed in the

cylinder is measured by the reduction in volume when the piston moves

from BDC to TDC, the actual proportional change in volume being

expressed as the compression-ratio.

MAJOR engine components

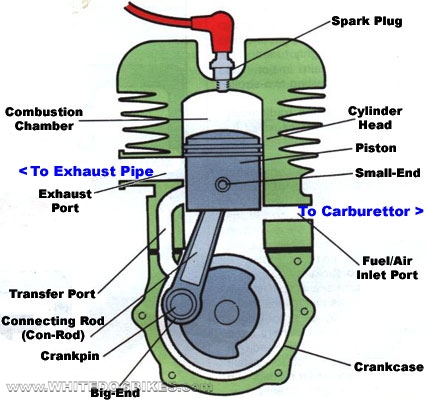

Identification of major engine components makes

it easier to understand its working principle. Some major engine

components are, cylinder block, piston, piston rings, connecting-rod,

cylinder head, crankcase, crankshaft etc. The following briefly

describes the major engine components and some terms associated with

them.

Cylinder block

This is a cast structure with cylindrical holes bored to guide and

support the pistons and to harness the working gases. It also provides a

jacket to contain a liquid coolant.

Cylinder head

This

casting encloses the combustion end of the cylinder block and houses

both the inlet and exhaust poppet-valves and their ports to admit air-

fuel mixture and to exhaust the combustion products.

Crankcase

This is a

cast rigid structure which supports and houses the crankshaft and

bearings. It is usually cast as a mono-construction with the cylinder

block.

Sump

This is a

pressed-steel or cast-aluminum-alloy container which encloses the bottom

of the crank-case and provides a reservoir for the engine's lubricant.

Piston

This is a

pressure-tight cylindrical plunger which is subjected to the expanding

gas pressure. Its function is to convert the gas pressure from

combustion into a concentrated driving thrust along the connecting-rod.

It must therefore also act as a guide for the small-end of the

connecting-rod.

Piston rings

These are

circular rings which seal the gaps made between the piston and the

cylinder, their object being to prevent gas escaping and to control the

amount of lubricant which is allowed to reach the top of the cylinder.

Gudgeon-pin

This pin

transfers the thrust from the piston to the connecting-rod small-end

while permitting the rod to rock to and fro as the crankshaft rotates.

Connecting-rod

This acts as

both a strut and a tie link-rod. It transmits the linear pressure

impulses acting on the piston to the crankshaft big-end journal, where

they are converted into turning-effort.

Crankshaft

A simple

crankshaft consists of a circular-sectioned shaft which is bent or

cranked to form two perpendicular crank-arms and an offset big-end

journal. The unbent part of the shaft provides the main journals. The

crankshaft is indirectly linked by the connecting-rod to the piston -

this enables the straight-line motion of the piston to be transformed

into a rotary motion at the crankshaft about the main-journal axis.

Crankshaft journals

These

are highly finished cylindrical pins machined parallel on both the

centre axes and the offset axes of the crankshaft. When assembled, these

journals rotate in plain bush-type bearings mounted in the crankcase

(the main journals) and in one end of the connecting-rod (the big-end

journal).

Small-end

This refers to

the hinged joint made by the gudgeon-pin between the piston and the

connecting-rod so that the connecting-rod is free to oscillate relative

to the cylinder axis as it moves to and fro in the cylinder.

Big-end

This refers to the

joint between the connecting-rod and the crankshaft big-end journal

which provides the relative angular movement between the two components

as the engine rotates.

Main-ends

This refers to

the rubbing pairs formed between the crankshaft main journals and their

respective plain bearings mounted in the crankcase.

Line of stroke

The centre path the piston is forced to follow due to the constraints of the cylinder is known as the line of stroke.

Inner and outer dead centers

When the crank arm and the connecting-rod are aligned along the line of

stroke, the piston will be in either one of its two extreme positions.

If the piston is at its closest position to the cylinder head, the crank

and piston are said to be at inner dead centre (IDC) or top dead centre

(TDC). With the piston at its furthest position from the cylinder head,

the crank and piston are said to be at outer dead centre (ODC) or

bottom dead centre (BDC). These reference points are of considerable

importance for valve-to-crankshaft timing and for either ignition or

injection settings.

Clearance volume

The space

between the cylinder head and the piston crown at TDC is known as the

clearance volume or the combustion-chamber space.

Crank-throw

The distance

from the centre of the crankshaft main journal to the centre of the

big-end journal is known as the crank-throw. This radial length

influences the leverage the gas pressure acting on the piston can apply

in rotating the crankshaft.

Piston stroke

The piston

movement from IDC to ODC is known as the piston stroke and corresponds

to the crankshaft rotating half a revolution or 180°. It is also equal

to twice the crank-throw.

i.e. L = 2R

where L = piston stroke

and R = crank-throw

Thus a long or short stroke will enable a large or small turning-effort to be applied to the crankshaft respectively.

Cylinder bore

The cylinder

block is initially cast with sand cores occupying the cylinder spaces.

After the sand cores have been removed, the rough holes are machined

with a single-point cutting tool attached radially at the end of a

rotating bar. The removal of the unwanted metal in the hole is commonly

known as boring the cylinder to size. Thus the finished cylindrical hole

is known as the cylinder bore, and its internal diameter simply as the

bore or bore size.

4 stroke cycle petrol engine

FOUR STROKE CYCLE S.I.(Spark ignition)/PETROL ENGINE.

Gasoline or petrol engines are also known as spark-ignition (S.I.) engines. Petrol engines take in a flammable mixture of air and petrol which is ignited by a timed spark when the charge is compressed. The first four stroke spark-ignition (S.I.) engine was built in 1876 by Nicolaus August Otto, a self-taught German engineer at the Gas-motoreufabrik Deutz factory near Cologne, for many years the largest manufacturer of internal-combustion engines in the world. It was one of Otto's associates - Gottlieb Daimler - who later developed an engine to run on petrol which was described in patent number 4315 of 1885. He also pioneered its application to the motor vehicle.

Four stroke Spark-ignition (S.I) engines require four

piston strokes to complete one cycle: an air-and-fuel intake stroke

moving outward from the cylinder head, an inward movement towards the

cylinder head compressing the charge, an outward power stroke, and an

inward exhaust stroke.

Induction stroke.

The inlet valve is opened and the exhaust valve is closed. The

piston descends, moving away from the cylinder head .

The speed of the piston moving along the cylinder creates a pressure

reduction or depression which reaches a maximum of about 0.3 bar below

atmospheric pressure at one-third from the beginning of the stroke. The

depression actually generated will depend on the speed and load

experienced by the engine, but a typical average value might be 0.12 bar

below atmospheric pressure. This depression induces (sucks in) a fresh

charge of air and atomized petrol in proportions ranging from 10 to 17

parts of air to one part of petrol by weight.

An engine which induces fresh charge by means of a

depression in the cylinder is said to be 'normally aspirated' or

'naturally aspirated'.

Compression stroke.

Both the inlet and the exhaust valves are closed. The

piston begins to ascend towards the cylinder head . The

induced air-and-petrol charge is progressively compressed to something

of the order of one-eighth to one-tenth of the cylinder's original

volume at the piston's innermost position. This compression squeezes the

air and atomized-petrol molecules closer together and not only

increases the charge pressure in the cylinder but also raises the

temperature. Typical maximum cylinder compression pressures will range

between 8 and 14 bar with the throttle open and the engine running under

load.

Power stroke.

Both the inlet and the exhaust valves are closed and, just

before the piston approaches the top of its stroke during compression, a

spark-plug ignites the dense combustible charge. By the

time the piston reaches the innermost point of its stroke, the charge

mixture begins to burn, generates heat, and rapidly raises the pressure

in the cylinder until the gas forces exceed the resisting load. The

burning gases then expand and so change the piston's direction of motion

and push it to its outermost position. The cylinder pressure then drops

from a peak value of about 60 bar under full load down to maybe 4 bar

near the outermost movement of the piston.

Exhaust stroke.

At the end of the power stroke the inlet valve remains closed

but the exhaust valve is opened. The piston changes its direction of

motion and now moves from the outermost to the innermost position. Most of the burnt gases will be expelled by the existing

pressure energy of the gas, but the returning piston will push the last

of the spent gases out of the cylinder through the exhaust-valve port

and to the atmosphere.

During the exhaust stroke, the gas pressure in the cylinder will

fall from the exhaust-valve opening pressure (which may vary from 2 to 5

bar, depending on the engine speed and the throttle-opening position)

to atmospheric pressure or even less as the piston nears the innermost

position towards the cylinder head.

4 stroke cycle diesel engine

FOUR STROKE CYCLE COMPRESSION IGNITION (DIESEL) ENGINE.

Compression-ignition (C.I) engines burn fuel oil which

is injected into the combustion chamber when the air charge is fully

compressed. Burning occurs when the compression temperature of the air

is high enough to spontaneously ignite the finely atomized liquid fuel.

In other words, burning is initiated by the self-generated heat of

compression (Fig. 1.1-8). Compression-ignition (C.I) engines are also

referred to as 'oil engines', due to the class of fuel burnt, or as

'diesel engines' after Rudolf Diesel, one of the many inventors and

pioneers of the early C.I. engine. Note: in the United Kingdom fuel oil

is known as 'DERV', which is the abbreviation of 'diesel-engine road

vehicle'.

Just like the four-stroke-cycle petrol engine,

the Compression-ignition (C.I.) engine completes one cycle of events in

two crankshaft revolutions or four piston strokes. The four phases of

these strokes are (i) induction of fresh air, (ii) compression and

heating of this air, (iii) injection of fuel and its burning and

expansion, and (iv) expulsion of the products of combustion.

Induction stroke.

With the inlet valve open and the exhaust valve closed, the piston moves away from the cylinder head.The outward movement of the piston will establish a depression in the cylinder, its magnitude depending on the ratio of the cross-sectional areas of the cylinder and the inlet port and on the speed at which the piston is moving. The pressure difference established between the inside and outside of the cylinder will induce air at atmospheric pressure to enter and fill up the cylinder. Unlike the petrol engine, which requires a charge of air-and-petrol mixture to be drawn past a throttle valve, in the diesel-engine inlet system no restriction is necessary and only pure air is induced into the cylinder. A maximum depression of maybe 0.15 bar below atmospheric pressure will occur at about one-third of the distance along the piston's outward stroke, while the overall average pressure in the cylinder might be 0.1 bar or even less.Compression stroke.

With both the inlet and the exhaust valves closed, the piston

moves towards the cylinder head.

The air enclosed in the cylinder will be

compressed into a much smaller space of anything from 1/12 to 1/24 of

its original volume. A typical ratio of maximum to minimum air-charge

volume in the cylinder would be 16:1, but this largely depends on engine

size and designed speed range.

During the compression stroke, the air charge

initially at atmospheric pressure and temperature is reduced in volume

until the cylinder pressure is raised to between 30 and 50 bar. This

compression of the air generates heat which will increase the charge

temperature to at least 600 °C under normal running conditions.

Power stroke.

With both the inlet and the exhaust valves closed and the

piston almost at the end of the compression stroke (Fig. 1.1 -8(c)),

diesel fuel oil is injected into the dense and heated air as a

high-pressure spray of fine particles. Provided that they are properly

atomized and distributed throughout the air charge, the heat of

compression will then quickly vaporize and ignite the tiny droplets of

liquid fuel. Within a very short time, the piston will have reached its

innermost position and extensive burning then releases heat energy which

is rapidly converted into pressure energy. Expansion then follows,

pushing the piston away from the cylinder head, and the linear thrust

acting on the piston end of the connecting-rod will then be changed to

rotary movement of the crankshaft.

Exhaust stroke.

When the

burning of the charge is near completion and the piston has reached the

outermost position, the exhaust valve is opened. The piston then

reverses its direction of motion and moves towards the cylinder head.

The sudden opening of the exhaust valve towards

the end of the power stroke will release the still burning products of

combustion to the atmosphere. The pressure energy of the gases at this

point will accelerate their expulsion from the cylinder, and only

towards the end of

the piston's return stroke will the piston actually catch up with

the tail-end of the outgoing gases.

2 stroke cycle diesel engine

.

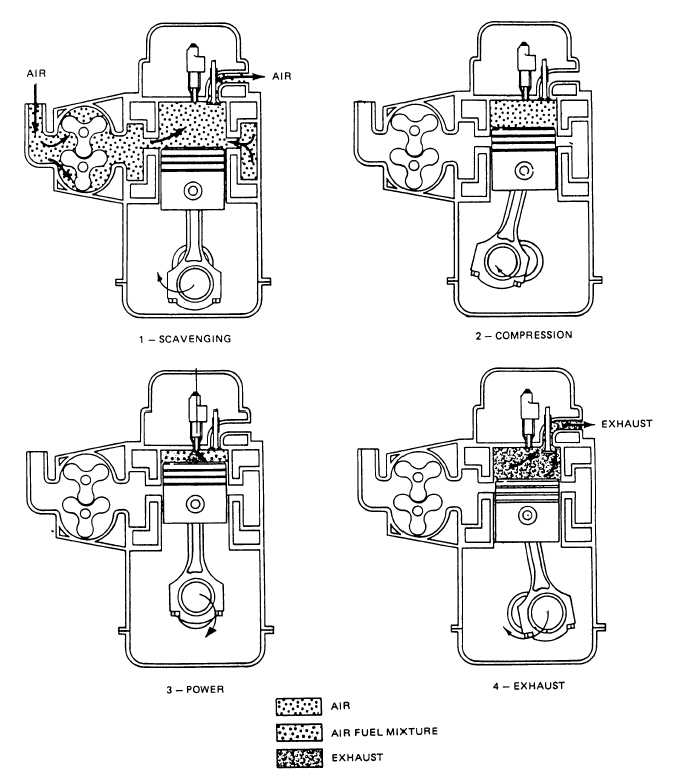

Two-Stroke Cycle Diesel Engine

A two-stroke diesel engine shares the

same operating principles as other internal combustion

engines. It has all of the advantages that other diesel

engines have over gasoline engines.

A two-stroke diesel engine does not produce as

much power as a four-stroke diesel engine; however, it

runs smoother than the four-stroke diesel. This is

because it generates a power stroke each time the piston

moves downward; that is, once for each crankshaft

revolution. The two-stroke diesel engine has a less

complicated valve train because it does not use intake

valves. Instead, it requires a supercharger to force air

into the cylinder and force exhaust gases out, because

the piston cannot do this naturally as in four-stroke

engines.

The two-stroke diesel takes in air and discharges

exhaust through a system called scavenging.

Scavenging begins with the piston at bottom dead

center. At this point, the intake ports are uncovered in

the cylinder wall and the exhaust valve is open. The

supercharger forces air into the cylinder, and, as the air

is forced in, the burned gases from the previous

operating cycle are forced out.

COMPRESSION STROKE.— As the piston

moves towards top dead center, it covers the intake

ports. The exhaust valves close at this point and seals

the upper cylinder. As the piston continues upward, the

air in the cylinder is tightly compressed . As

in the four-stroke cycle diesel, a tremendous amount of

heat is generated by the compression.

POWER STROKE.— As the piston reaches top

dead center, the compression stroke ends. Fuel is

injected at this point and the intense heat of the

compression causes the fuel to ignite. The burning fuel

pushes the piston down, giving power to the crankshaft.

The power stroke ends when the piston gets down to the

point where the intake ports are uncovered. At about this

point, the exhaust valve opens and scavenging begins

again

.

Valve Train

The operation of the valves in a timed sequence is

critical. If the exhaust valve opened in the middle of the

intake stroke, the piston would draw burnt gases into the

combustion chamber with a fresh mixture of fuel and

air. As the piston continued to the power stroke, there

would be nothing in the combustion chamber that would

2 stroke cycle petrol engine

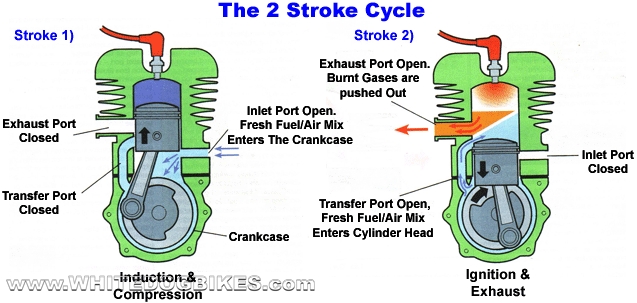

A Very Basic 2 Stroke Engine

Please note-the diagram below represents a very simple version of a 2 stroke engine, in reality, they are a little bit more complicated!!!Engine Terminology

Stroke: Either the up or

down movement of the piston from the top to the bottom or

bottom to top of the cylinder (So the piston going from the

bottom of the cylinder to the top would be 1 stroke, from

the top back to the bottom would be another stroke)

Induction: As the piston

travels down the cylinder head, it 'sucks' the fuel/air mixture

into the cylinder. This is known as 'Induction'.

Compression: As the piston

travels up to the top of the cylinder head, it 'compresses'

the fuel/air mixture from the carburetor in the top of the

cylinder head, making the fuel/air mix ready for igniting

by the spark plug. This is known as 'Compression'.

Ignition: When the spark

plug ignites the compressed fuel/air mixture, sometimes referred

to as the power stroke.

Exhaust: As the piston returns

back to the top of the cylinder head after the fuel/air mix

has been ignited, the piston pushes the burnt 'exhaust' gases

out of the cylinder & through the exhaust system.

Transfer Port: The port (or

passageway) in a 2 stroke engine that transfers the fuel/air

mixture from the bottom of the engine to the top of the cylinder

The 2 Stroke Cycle

We have simplified this explanation as much as possible so some of the 'correct' terms have been replaced. There are many more factors which enable an engine to run, such as fuel/air ratios, ignition timing & shaped piston heads (extensively used in 2 stroke engines) but the explanation below outlines the basic differences between 2 & 4 stroke engine operation.

Stroke

|

Piston Direction

|

Actions Occurring during

This Stroke

|

Explanation

|

Stroke 1

|

Piston travels up the cylinder barrel

|

Induction & Compression

|

As the Piston travels up the barrel,

fresh fuel/air mix is sucked into the crankcase (bottom

of the engine) & the fuel/air mix in the cylinder

(top of the engine) is compressed ready for ignition

|

Stroke 2

|

Piston travels down the cylinder

barrel

|

Ignition & Exhaust

|

The spark plug ignites the fuel/air

mix in the cylinder, the resulting explosion pushes

the piston back down to the bottom of the cylinder,

as the piston travels down, the transfer port openings

are exposed & the fresh fuel/air mix is sucked from

the crankcase into the cylinder. As the fresh fuel/air

mix is drawn into the cylinder, it forces the spent

exhaust gases out through the exhaust port.

|

CAR (toyota) wallpapers

Subscribe to:

Posts (Atom)

.gif)